COVID-19 update from Encore Garage

Our showroom is now open daily! We continue to honor safety protocols while practicing social distancing. Come see us soon.

Flooring

Our Process

Over the years, we have tested a variety of alternatives and found that nothing beats the core strength of an industrial epoxy base combined with the flexibility of a Polyaspartic topcoat. While other firms may offer a one-day process using an “in and out” installation method with products that allow for quick application, we remain committed to the details of our two-day installation process that allows each layer to properly bond and cure. Taking the extra steps necessary, utilizing the highest quality products, and employing only full-time, highly trained technicians is what guarantees the integrity of the Encore system. It allows us to offer a lifetime warranty against lifting, chipping, or peeling on every residential floor we install.

Watch our Day 1 stepsTo start, we use diamond tip grinders to completely clean and prepare the concrete. Each crew carries a full range of diamond tooling so they can adapt to every type of concrete. This important step is vital in creating the proper surface for a durable bond and is a prime differentiator between our process and many other vendors in the market. After this first step, the concrete is like a sponge – ready to absorb and lock in the base layer of chemicals. Simple acid washes, sanding or brushing techniques do not create enough of a textured surface for durable bonding of any coating.

We test all floors for moisture content, applying a separate seal coat as needed. If any portion of the floor tests high, we seal the entire floor. While this moisture barrier adds a day to our process, we will not rush a job – ensuring that your floor will stand up to the challenging heat and humidity of Southwest Florida.

For any cracks, divots, or minor imperfections, we use an advanced, fast-curing polymer patching material to create a smooth surface. (Please note that we do not fill existing open expansion joints and strongly recommend that they remain in place.)

We then apply a pigmented base coat of an industrial-grade epoxy, made of 100% solids, to create the strongest possible bond with the exposed concrete surface. This is not retail grade, paint-on epoxy which will often peel and lift after only a short time – we use an industrial product sourced direct from a global manufacturer of flooring chemicals, with specific requirements for usage and application techniques. While there are a number of alternatives currently available, our epoxy is rated at over 7,500 PSI, more than twice the rating of most concrete. After 14 years of successful installations we have not found a product that bonds better with concrete floors in Southwest Florida.

While the base coat is still wet, we completely cover the floor with a full broadcast of colored PVC flakes giving the floor its dynamic pattern. The floor is then left overnight to properly cure – forming the lasting foundation of our system. While we have over 20 different colored flake blends in stock and ready to go, your choices are truly endless. For a small upcharge, we can custom blend flakes to create the perfect look for your garage floor.

For clients interested in a truly seamless look, we offer matching “baseboard” molding that is custom made in our shop from water resistant cement backer board. Available in any height from 4” to 12”, our baseboard provides the added benefit of creating a water resistant “bowl” around the floor, making it exceptionally easy to clean the entire space with a garden hose with no worries of water damage to exposed drywall or wood molding.

Once cured, the excess flakes are scraped away to reveal the “orange peel” texture of the floor. Because we broadcast a thick layer of flakes on Day 1, our finished product achieves 95-98% coverage.

Our final step is a Polyaspartic topcoat. This is perfect for concrete floors in Southwest Florida because it is stain-resistant, will not yellow over time, and provides flexibility due to its strong elongation properties even when fully cured. Our topcoat has been specifically tested to work with high-performance tires even in our hot weather climate. Easy cleaning with ammonia and water or Simple Green will keep your floor looking great for years to come.

Once the topcoat is down, you can walk on the floor after eight hours and drive on it after 24 hours.

Flooring Key Benefits

Key features of our multi-layer flake flooring system:

- Beauty and durability: an attractive, high-quality floor that complements the design of your property

- An extensive range of standard and customizable options allow you to select a color blend based on your personal preferences

- The finished product has a non-porous finish with no crevices to trap dirt and grime. It is highly stain-resistant, even against high-performance tires

- The system is UV resistant and will not yellow over time

- It is easy to keep clean with regular sweeping and an occasional rinse with a hose. When needed, tougher cleaning can be accomplished with ammonia and water or Simple Green

- Will not chip, peel or lift, even under hot tires and is rated for commercial use

- We use mechanical grinders with diamond tooling for surface preparation which is the only way to ensure a proper bonding of our system to the concrete. It is far superior to an acid or solvent "wash" method often used by others in the industry

- We use only 100% solids epoxy base coat for our "foundational layer" because nothing penetrates the pores better or creates a stronger bond with the concrete. This ensures the floor will not blister or peel – even under the tires

- We use a full broadcast of vinyl chips for both appearance and added strength

- We use a Polyaspartic topcoat that has been specifically tested and proven to be effective in SWFL. The elongation properties give the system it’s flexibility and offer a high resistance to impact, abrasion and hot temperatures

- Our process is completed over two days followed by a 24-hour cure time – getting your garage back in service quickly

- Other than cleaning, there is no regular maintenance required

- You receive a complete warranty – materials and labor – against lifting, chipping, or peeling for as long as you own your property

Flooring Frequently Asked Questions

-

What type of flooring chemicals do you use?

We use a 100%-solids industrial epoxy for the base coat. It is a technology proven over many years – nothing bonds better to your concrete to form a foundation for flake or quartz flooring. In fact, our epoxy is rated at over 7,500 PSI, more than twice the strength of most concrete, so it actually strengthens the surface for broadcasting of the flakes. For the top coat, we use a Polyaspartic coating that remains flexible even when cured to resist lifting, chipping and peeling. The specific product we use is optimized to resist staining, even from the plasticizers in high performance tires.

-

Is the floor slippery?

All garage floors can be slippery, especially when wet. Our standard decorative flake floor does result in an “orange peel” texture but is technically not to be considered “anti-slip”. For clients concerned about a slippery floor, Encore offers an option of a second topcoat that includes a “grip additive” that mitigates the floor becoming slippery. For those interested in the best traction, clients can consider our quartz aggregate flooring system which is designed to meet anti-slip requirements even in commercial applications.

-

How do you prepare the floor before coating it?

New or old we always prepare the concrete through a mechanical abrasion procedure using high-powered diamond grinders. Depending on existing coatings and the condition of the concrete, we may take two or three passes to properly grind the floor. This cleans the top surface and “opens the pores” of the concrete allowing our base coat to penetrate deeply for excellent adhesion. This process is typically considered to be an industry wide best practice for obtaining a consistent surface profile and is superior to the acid method used by others in the industry.

-

Can you just go over my current coating?

Unfortunately, that is not an option with our process. On average, about 80% of our residential work starts with removing the existing coating because it has started to fail or is permanently stained. To make our process work we must start with a pristine, freshly ground floor.

-

I have some cracks and pitting. Can you repair this condition?

Generally, yes. We utilize a fast-curing polymeric patching system that works extremely well and is compatible with our other chemicals. This approach is used on all pitting, divots and cracks, with several layers being applied if the crack is particularly wide or deep. If you have areas where the concrete has shifted up or down, more extensive repairs may be necessary.

-

How long does the entire process take?

The floor installation normally takes two days. You can return your car to your garage in 24 hours depending on weather conditions. Some companies complete a floor in one day with a morning base coat and afternoon top coat – presenting the quick turnaround as a benefit to you. We respectfully disagree. To finish in one day, the cure times of the base coat must be chemically accelerated, and the conditions required for proper curing are much narrower than our epoxy. We choose to do the grind and flakes on Day 1, allowing a full cure overnight before applying the top coat on the morning of Day 2. It’s a few extra hours but we think it’s worth it to get our lifetime warranty.

-

What do we do with all our garage “stuff” while the work is being done?

Encore can provide a 6’ x 6’ x 12’ storage trailer for your “stuff” for a fee of $100. Please check to make sure this is allowed in your development beforehand. So you have plenty of time to move everything, we will drop it off the day before your project begins and pick it up the day after we are finished. If you prefer, for a nominal fee our crew will load and unload the trailer for you. Our crew can also help you move larger items such as refrigerators and store them under a tarp in the driveway or in a side yard or patio.

-

What is your payment policy?

We typically schedule 4-8 weeks in advance and request a 50% deposit to reserve a spot our schedule. The balance is due three days after completion, so you have plenty of time to inspect our work and ensure you are satisfied with the finished product and our workmanship.

-

What is the warranty?

Your residential garage floor coating is warrantied against lifting, chipping or peeling for as long as you own the property. Importantly, the guarantee from Encore Garage of SWFL covers both materials and labor – we are not simply passing along a technical guarantee from our chemical manufacturers. Specific exceptions include surface damage from acid spills (e.g. battery acid from a golf cart) and cuts/abrasions caused by saws, forklifts, etc., as well as any failure of the underlying concrete structure.

-

How do I clean my new floor?

Keeping loose dirt off the floor with a broom or blower is always a good idea. For a more thorough cleaning we recommend occasionally washing the floor with a solution of five parts water to one part ammonia and a deck brush. Rinse off with a garden hose and use a foam squeegee to remove the excess water. To remove more stubborn dirt, we suggest using Simple Green as many traditional soaps and detergents can leave a buildup.

-

How long will my floor last?

With proper care and normal use your floor should last for as long as you own the property.

-

Do the chemicals smell during installation?

The Polyaspartic topcoat will have some odor as it cures but is not toxic. It will typically dissipate in a day or two.

Flooring Samples

-

Iced Coffee 1/4 (T)

-

Sanibel 1/4 (T)

-

Mojave 1/4 (T)

-

Gulfshore 1/4 (T)

-

Sedona 1/4 (T)

-

Iced Coffee 1/8 (T)

-

Scottsdale 1/8 (T)

-

Sedona 1/8 (T)

-

Dory 1/4 (G)

-

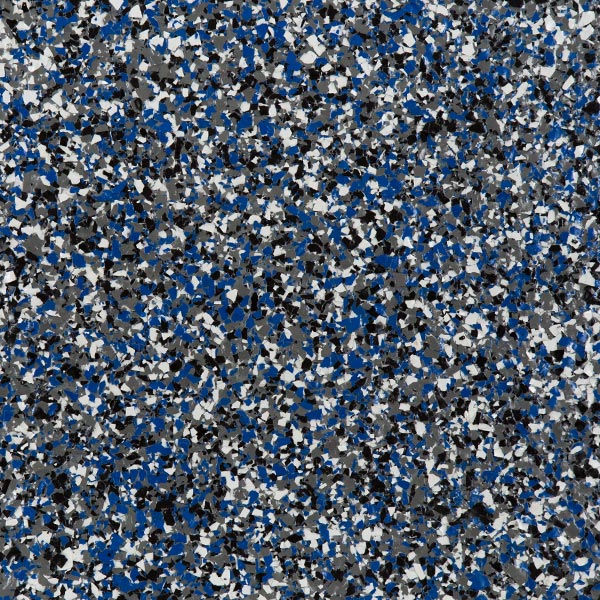

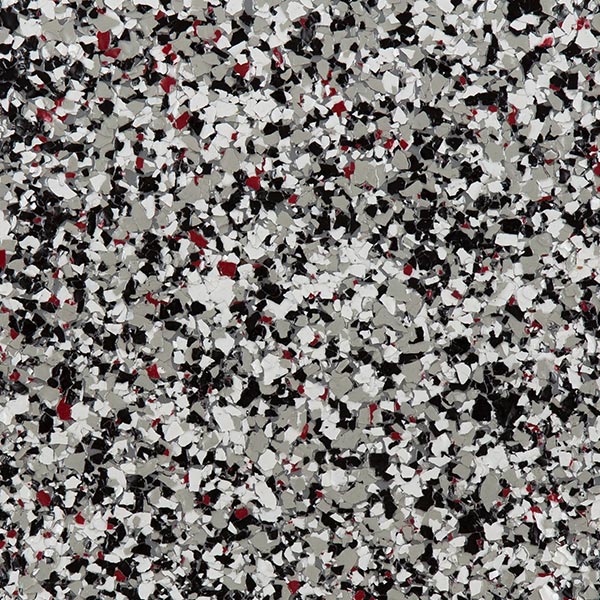

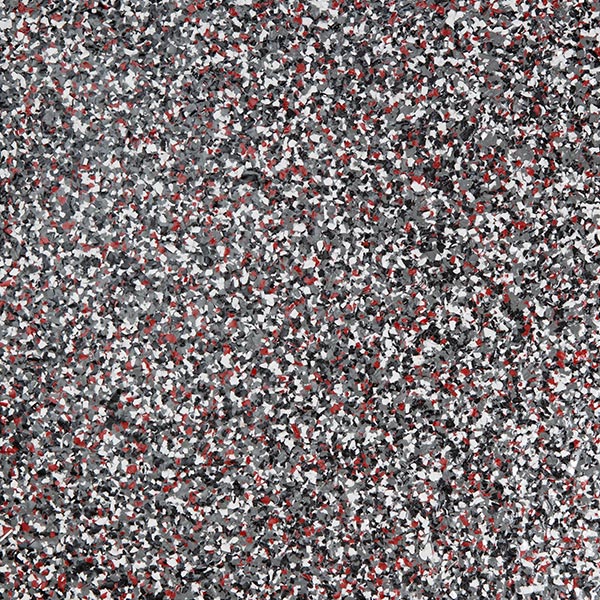

Blue Mist 1/4 (G)

-

Tidal Wave 1/4 (G)

-

Key West 1/4 (G)

-

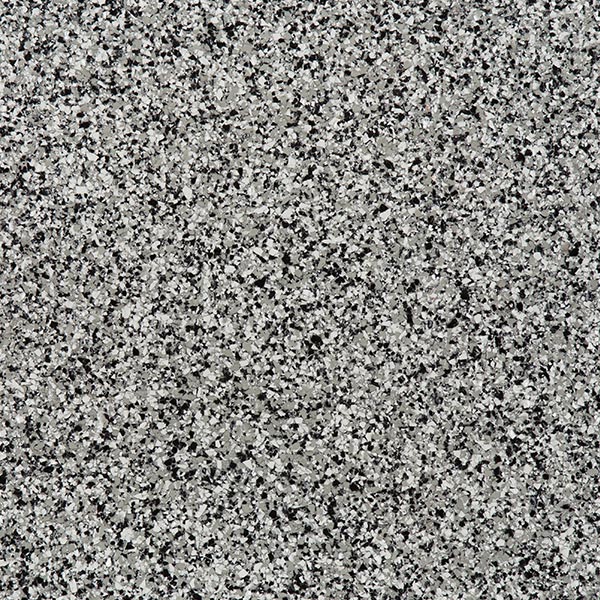

Smoke 1/4 (G)

-

Blue Ice 1/4 (G)

-

Stonehenge 1/4 (G)

-

Silver Bell 1/4 (G)

-

Red Smoke 1/4 (G)

-

Red Ice 1/4 (G)

-

California 1/4 (G)

-

Creekbed 1/4 (G)

-

Stone 1/4 (G)

-

Volcanic Beach 1/4 (G)

-

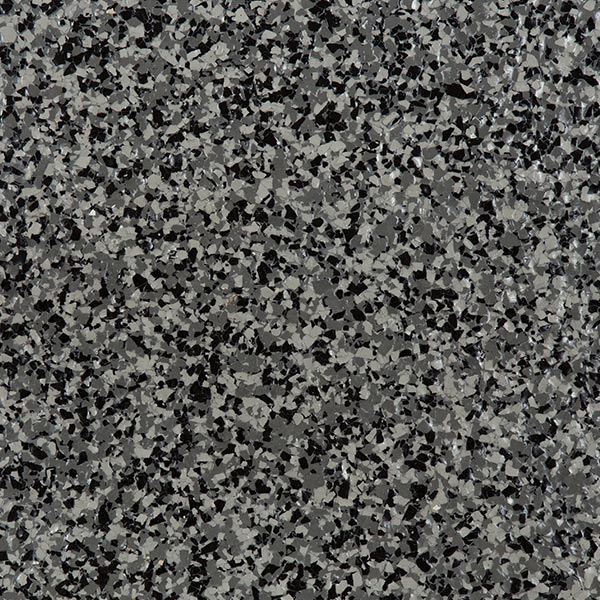

Graphite 1/4 (G)

-

Volcanic Beach 1/8 (G)

-

Graphite 1/8 (G)

-

Smoke 1/8 (G)

-

Silver Bell 1/8 (G)

-

Stone 1/8 (G)

Base Colors: (C) = Cream, (T) = Tan, (G) = Grey

Custom Colors Available

Get a Free Estimate Today!

Whether you live in Naples, Fort Myers, Marco Island, or virtually anywhere throughout Southwest Florida, our services are available to you.

Get a Free Estimate Call (239) 949-5584